THE GLAZE REPORT with Peter

We recently added an iron red glaze to the lineup at the studio!

Iron red glazes are notoriously finicky- a slight variation in the amounts of ingredients, different ingredient sources, firing temperature, placement in the kiln, cooling rate, thickness of application, etc. can all make or break an iron red glaze. I (Peter) tried all summer to nail down a good iron red- I got blacks, browns, and several iron sh** browns, but a good red color evaded me. Of course, the first iron red recipe Reid suggested we test for the studio worked on the first try! The recipe comes from Tony Hansen who runs DigitalFire. (Let us know if you want the link!).

What we’ve observed with this glaze so far:

The glaze applies very nicely- just mix it well first. We’ve added some bentonite to it since it was trying to hard pan….

When fired, it can be just slightly runny if thickly applied.

It’s glossy, and food safe.

It seems to look better on tan stoneware than over white slip (though the jury on that is still out…), and so far it’s looked great on the red clay.

Some may be interested to note: like nearly all iron reds, this glaze contains bone ash (a finer grade of what is in many plant fertilizers!). It’s a common glaze ingredient- pretty much the only way to add phosphorous to a glaze (needed for the iron red), but currently this is our only studio glaze that uses it.

In the photos, there’s some really interesting stuff going on with this glaze:

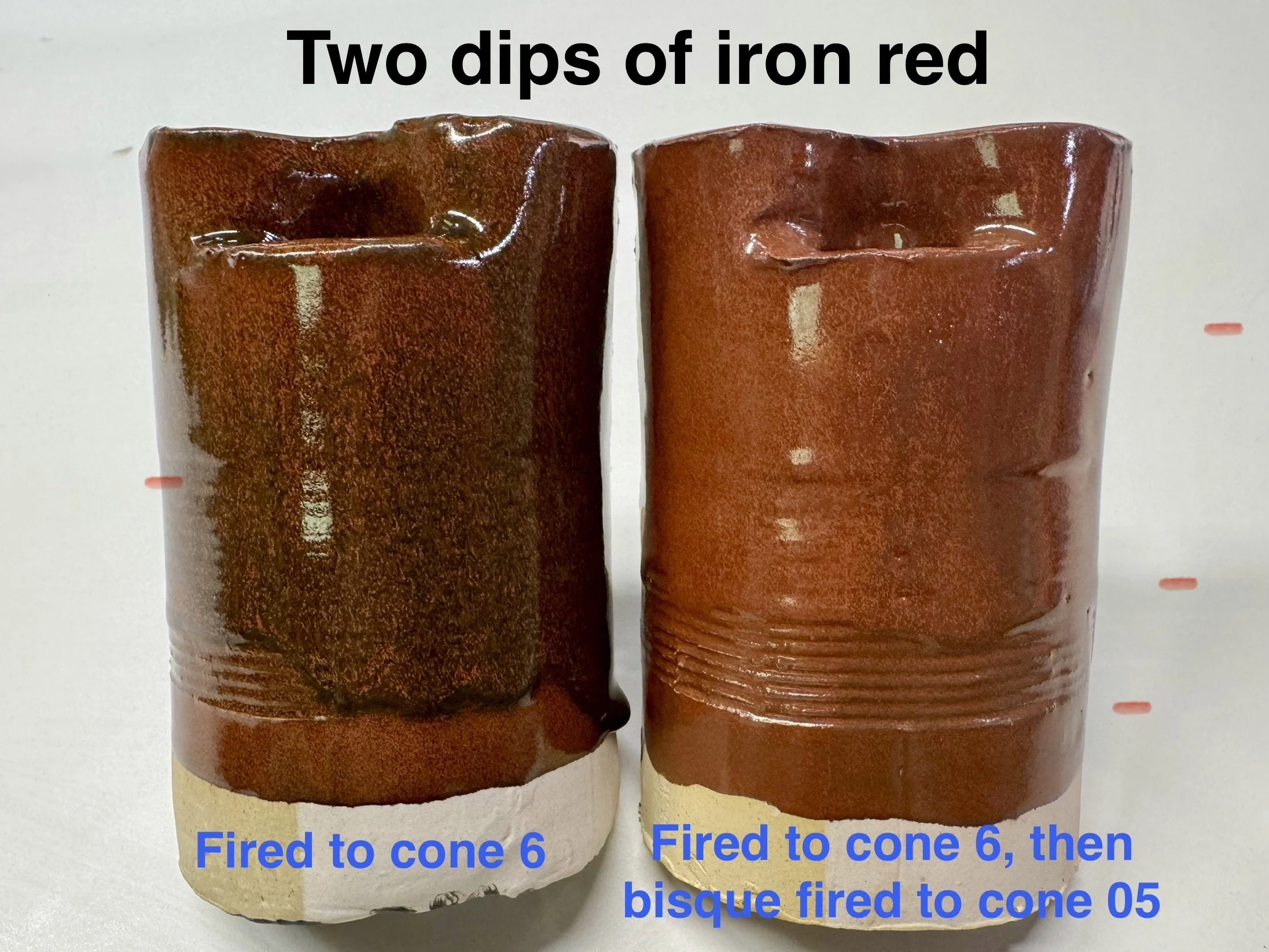

In the photo of the two tiles each with two dips of the iron red glaze, the one on the left was fired in a regular cone 6 firing. But the one on the right? We put that through a bisque firing after the glaze firing. Why? The micro-crystals that make that iron red color grow in roughly the 1,800 to 1,900 degree range. So doing a post-glaze bisque firing can increase the amount of red vs brown/black. Such cool glaze chemistry!

Iron red under the glossy white gives a super cool mottled effect. Here’s what I think is happening: both glazes are fluxed with boron Frit, particularly the white. As temperatures pass cone 3 or so, both glazes will already have begun melting (boron melts over a wide range of temperatures)- and at these higher temperatures, some of the iron oxide will release some oxygen (converting from Fe2O3 to FeO). As this oxygen gas bubbles up and out, it brings some of the iron red glaze to the surface with it. This is the process that makes oil spot glaze effects. But whatever the process, the result looks cool! Iron red over the glossy white gives a more slightly mottled brown.

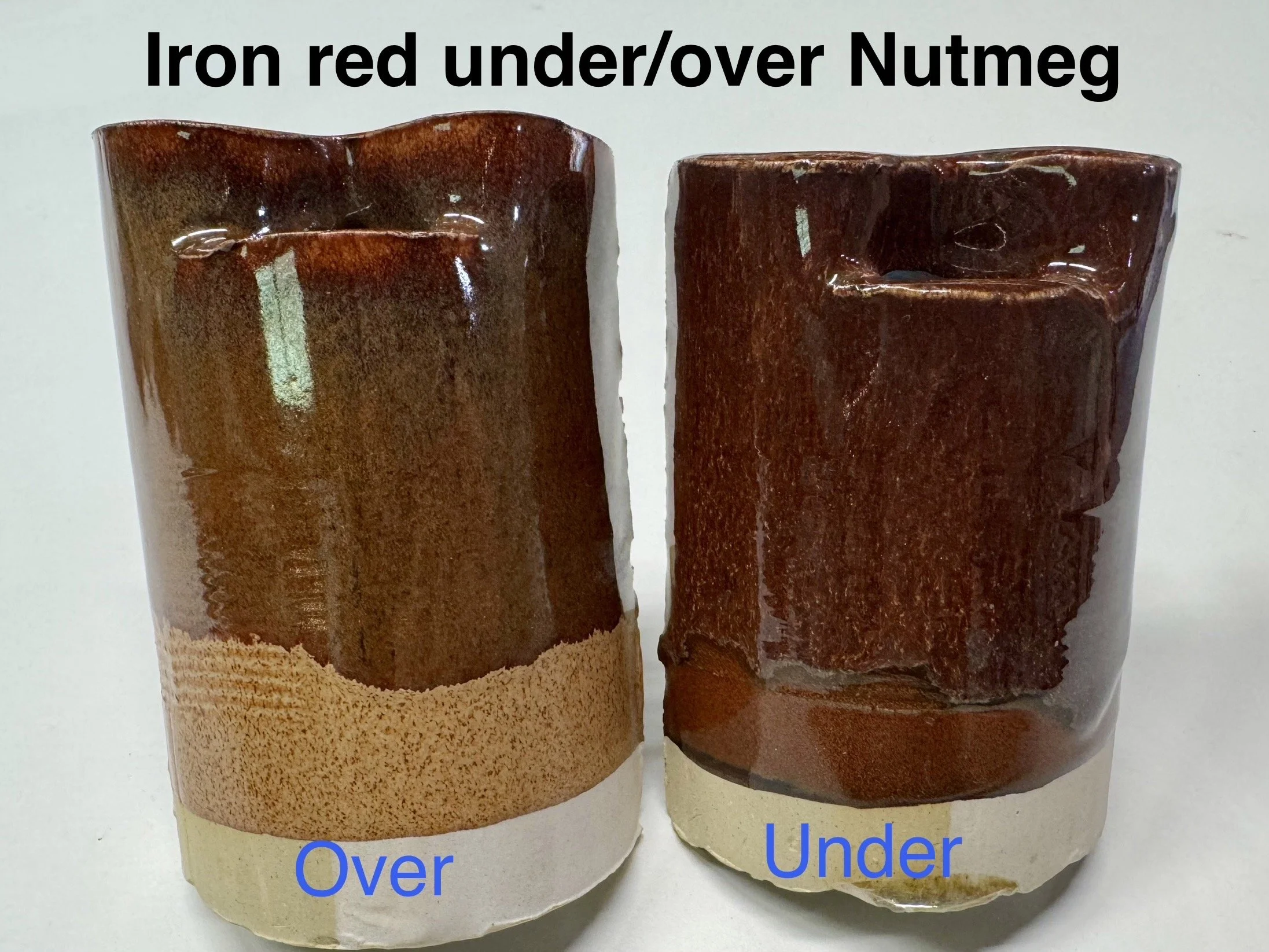

Iron red under and over the nutmeg yields more subtle effects. Iron red on top gives a really subtlety complex set of colors- greens, blues, browns, and almost crystal-y red. Iron red underneath gives a slightly darker, almost maroon color.

Iron red and clear are really weird! Iron red on top gives a rather drab greenish brown- not so pretty in my opinion. Iron red underneath is all over the place- from the usual iron red look to something akin to a floating beige/blue!

Iron red under the satin white gives a beautiful glossy finish with a slate brown/blue color- a real surprise! (Ok, I forgot to do a tile with the satin white underneath the iron red- but that’ll be in the next firing!).